Despite the fact 71% of Brits agreed that Fast Fashion is one of the largest contributors to the current climate crisis – 45% have admitted that they actually don’t care about the impact of their purchasing

Shocking new research has uncovered Brits views and understanding of the role fast fashion plays on the detrimental effects on the environment.

Whilst 71% of those polled agree that fast fashion is one of the largest contributors to the current climate crisis, the study found that 45% of Brits DON’T actually think about the environmental impact of their purchasing when buying from fast fashion retailers.

Nevertheless, whilst millions of Brits admit that they should be doing more to stem their consumption of fast fashion, 79% believe that there is more to be done by businesses to inform the public of the environmental impact of the clothing they purchase.

In addition, 70% of the nation think consumers/shoppers have a right to know how much carbon has been created in the manufacturing of their garments and 59% of people believe that all clothes should come with an environmental efficiency rating so consumers are able to make an informed choice.

Of those polled 65% said they would be more likely to buy a clothes garment if it was rated green (Eco-Friendly) over red (Environmentally damaging). With a further 41% admitting that they would change their buying habits if they knew the true environmental impact of their purchasing.

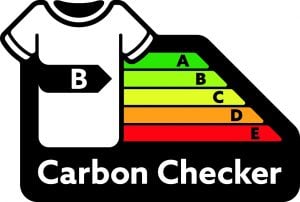

The research was commissioned by the Christopher Nieper Foundation who are calling on the government to create a Carbon Checker, an environmental initiative for kite marks for clothing to take steps towards net-zero in the industry and incentivise the sector to compete for the most sustainable supply chains.

The research also revealed 50% of Brits currently purchase 1-5 brand new items of clothing each month which equates to a mammoth 60 items of clothing per year per brit. However, many of these purchases never see the light of day with 41% of Brits admitting that they often return items of clothing that they bought online.

Of those returning items 56% of the nation say that when returning new clothes, they DON’T consider the additional impact it may have on the environment.

Shockingly, 17% said that if they knew the true value of the environmental impact of their purchasing, they wouldn’t change their buying habits at all.

Christopher Nieper OBE, CEO of clothing manufacturer David Nieper which has been sustainably making clothes in Britain for 60 years and head of the Foundation said: “The fashion sector is worth £26billion and Britain is a world leader in fashion design and fashion education, yet nearly everything we wear is imported. For too long the clothing industry has ignored the consequence of emissions which has led to long-distance supply chains and production in countries with very low proportions of sustainable energy.”

“Coupling this with the UK public’s current consumption of fast fashion this has created a recipe for disaster for the world’s climate, it is time now to be better informed as a nation about the problems our consumption causes and to single out those brands not doing enough to support the move to net-zero. Making fashion in the UK is highly effective and the opportunity for job creation is huge. even a small increase in UK-sourced manufacturing could generate tens of thousands of new jobs here. If consumers knew the environmental footprint of garments at the point of purchase it would at last be possible to choose planet-friendly garments over planet-damaging versions. This in turn should incentivize the sector to compete for the most sustainable supply chains. Our suggested approach is to form an advisory group, a consortium of organisations which is both geographically diverse and representative of the wider UK fashion and textile industry. And our challenge to government is to act now and introduce carbon checker labels to give consumers a choice and our planet a chance.”

To join the initiative visit: https://petition.parliament.uk/petitions/598973

For full story see here

Notes for editors:

David Nieper LTD

David Nieper LTD is family company with 280 staff which has designed and manufactured fashion exclusively in England for 60 years, proving sustainable manufacture is possible in Britain.

Christopher Nieper OBE is the Chief Executive of the Derbyshire clothing manufacturer and joined the business in the 1980s, a time when most British fashion companies moved their manufacturing overseas. Christopher made the decision to keep the firm’s manufacturing base in the East Midlands.

Today, David Nieper, which designs, manufactures and sells premium women’s clothing, is one of Alfreton’s largest employers with more than 300 staff.

In the 2020 New Year’s Honours List, he was made an OBE for services to UK manufacturing and apprenticeship development.

The focus of the company’s new carbon checker innovation will be to quantify the practical steps towards net-zero emissions and create a fashion labelling system which informs consumers.

The company wants Britain to lead the way to net zero for the world’s most polluting industry and by doing so create new sustainable jobs and manufacturing opportunities around the UK as well as incentivise fashion to clean up its act and to stop buying fashion on the other side of the world where pollution is out of sight and out of mind.

The carbon checker will be based on an academic partnership to create robust scientific models which will measure and categorise a garment’s carbon footprint and translate it into a meaningful rating for consumers to understand ‘at a glance’ the eco credentials of their purchase, similar to food labelling and white goods.

To join the initiative visit: https://petition.parliament.uk/petitions/598973

For more information please contact: [email protected]